EPOXY / PU PRIMER

Neo has extensive range of primers based on Epoxy / PU / Synthetic Resins. NEO PRIME GUARD grades are quality Epoxy based primers while NEO SHIELD PRIME grades are PU primers. These are used as a primer. They exhibit excellent adhesion properties and will stick to bare metal, Paints, primers, and fillers. They are used as a anti corrosive / protective primers. Neo offers multiple grades loaded with special additives, pigments for meeting specific requirements.

Surface Preparation:

Abrasive blasting to Sa 2 ½ Swedish standards is the best method of surface preparation. In

case blasting is not possible, then the surface of steel should be cleaned to St-2/St-3. The

surface should be absolutely dry, moisture and oil free before primer application.

Application Method:

Stir the Base part thoroughly. Mix base and Hardener as per our recommended ratio, by

volume, Allow the mixture to stand still (maturation) for about 10-15 minutes to initiate

the reaction. Add suggested Thinner into mix, if required, depending on application method,

and stir gently for few minutes. Stain the paint through nylon filter cloth of 100 mesh size

and apply uniformly over the surface. All equipment used for above should be properly

cleaned. Apply By Brush/By Conventional spray.

Shop at:

Product Grades:

- NEO PRIMEGUARD 5000

- NEO PRIMEGUARD 5001

- NEO PRIMEGUARD 5002

- NEO PRIMEGUARD 5003

- NEO PRIMEGUARD FR 5005

- NEO PRIMEGUARD FD 5020

- NEO PRIMEGUARD HB 5010

- NEO PRIMEGUARD HBHS 5055

- NEO SHIELD PRIME 6000

- NEO SHIELD PRIME 6010

- NEO PRIME FDS 4000

- NEO PRIME 4010

- NEO SYN PRIME 4011

- NEO PRIME 4022

- NEO PRIME 2000

- NEO PRIME FD 4030

- NEO PRIMEGUARD 5100

- NEO PRIME 9000

| Product Code | RECOMMENDED USE |

|---|---|

| NEO PRIMEGUARD 5000 | General purpose protective primer. Good resistance to chemical atmosphere. can be top coated with Epoxy, Acrylic & polyurethane Paints. It is recommended as primer on M.S Surface for OEM’s as well as for process industries like fertilizers, refineries, chemical and other plants. It can also be applied in diverse areas of tank exteriors, equipment’s, pipelines, structural steel, etc. |

| NEO PRIMEGUARD 5001 | General purpose protective anti corrosive primer. Good resistance to marine & chemical atmosphere. can be top coated with Epoxy, Acrylic & polyurethane Paints. It is recommended as primer on M.S Surface for OEM’s as well as for process industries like fertilizers, refineries, chemical and other plants. It can also be applied in diverse areas of tank exteriors, equipment’s, pipelines, structural steel, etc. |

| NEO PRIMEGUARD 5002 | General purpose protective anti corrosive primer. Good resistance to marine & chemical atmosphere. Good abrasion resistance, chrome free, can be top coated with Epoxy, Acrylic & polyurethane Paints. It is recommended as primer on M.S Surface for OEM’s as well as for process industries like fertilizers, refineries, chemical and other plants. It can also be applied in diverse areas of tank exteriors, equipment’s, pipelines, structural steel, etc. |

| NEO PRIMEGUARD 5003 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like fertilizers, refineries, chemical and other plants. It can also be applied in diverse areas of tank exteriors, equipment’s, pipelines, structural steel, etc. Not to be used for immersion application. |

| NEO PRIMEGUARD FR 5005 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like fertilizers, refineries. It can also be applied in diverse areas of tank exteriors, equipment’s, pipelines, structural steel, etc. Not to be used for immersion application. |

| NEO PRIMEGUARD FD 5020 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like fertilizers, refineries. It can also be applied in diverse areas of tank exteriors, equipment’s, pipelines, structural steel, etc. Not to be used for immersion application. |

| NEO PRIMEGUARD HB 5010 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like refineries, chemical and other plants. It can also be applied in diverse areas of tank exteriors, equipment’s, pipelines, structural steel, etc. Not to be used for immersion application. |

| NEO PRIMEGUARD HBHS 5055 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like refineries, chemical and other plants. It can also be applied in diverse areas of tank exteriors, equipment’s, pipelines, structural steel, etc. Not to be used for immersion application. |

| NEO SHIELD PRIME 6000 | It is recommended as primer on M.S Surface for OEM’s and Auto ancillaries as well as for process industries like, refineries, chemical and other plants. It can also be applied in diverse areas of tank exteriors, equipment’s, structural steel, immersion application& pipelines for good chemical resistance. |

| NEO SHIELD PRIME 6010 | It is recommended as primer on M.S Surface for OEM’s and Auto ancillaries as well as for process industries like, refineries, chemical and other plants. It can also be applied in diverse areas of tank exteriors, equipment’s, structural steel, immersion application& pipelines for good chemical resistance. |

| NEO PRIME FDS 4000 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like farm equipment’s, refineries, chemical and other plants. |

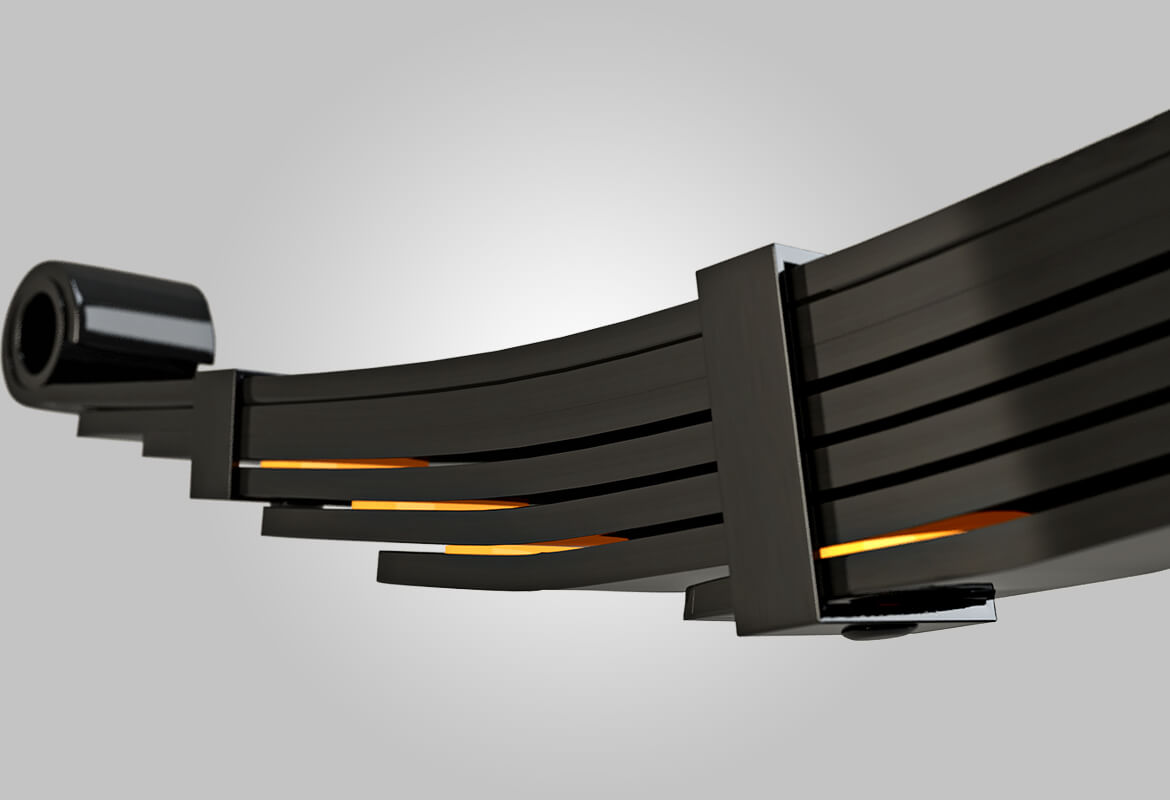

| NEO PRIME 4010 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like farm equipment’s, transformers, and refineries, and other plants. |

| NEO SYN PRIME 4011 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like farm equipment’s, Water tanks, auto ancillaries, and pipe line coatings, and other plants. |

| NEO PRIME 4022 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like farm equipment’s, Water tanks, auto ancillaries, and pipe line coatings, and other plants. |

| NEO PRIME 2000 | It is recommended as primer on M.S Surface for OEM’s as well as for process industries like farm equipment, Auto ancillaries, and pipe line coatings, and other plants. |

| NEO PRIME FD 4030 | It is recommended as primer on M.S Surface for OEM’s, Auto ancillaries as well as for process industries like farm equipment’s, refineries, chemical and other plants. |

| NEO PRIMEGUARD 5100 | Anti corrosive intermediate primer for steel structures such as Bridges, plant equipments, storage tanks, process industries like fertilizers, refineries, chemical and other plants. |

| NEO PRIME 9000 | It is recommended for Aluminium, Galvanized Steel surfaces which offer excellent adhesion and good anti-corrosive properties. Etch primer is recommended for coating Bus body, Chassis, & auto ancillaries etc. |